Company Profile

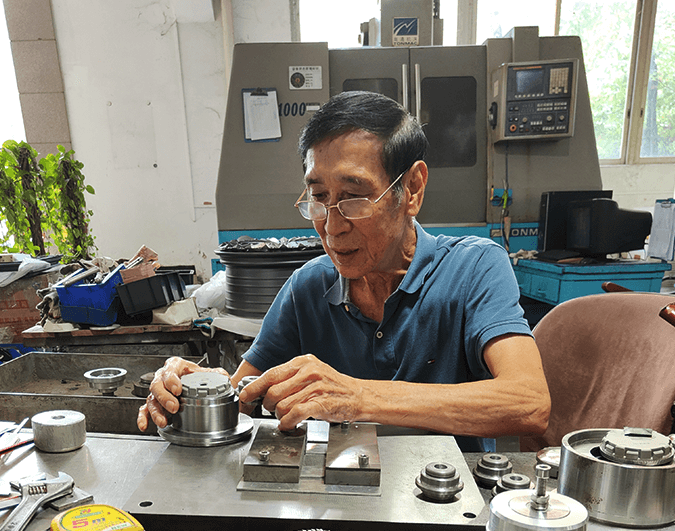

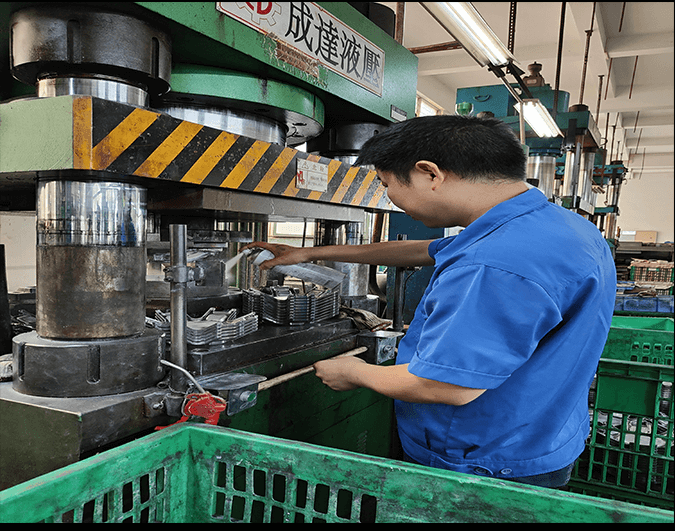

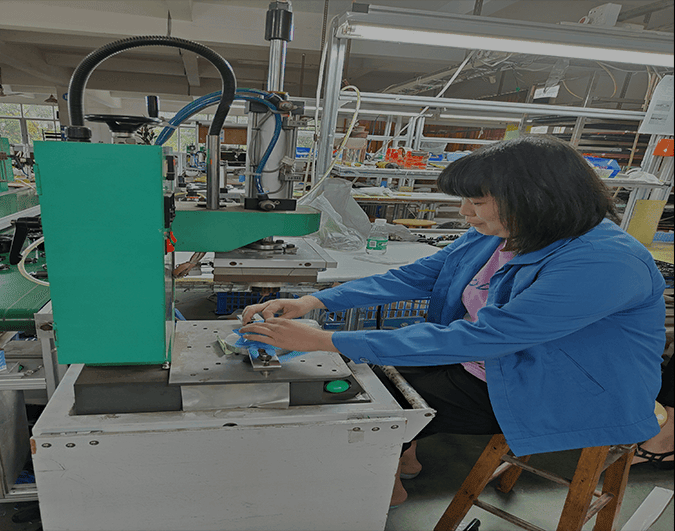

Foshan Bozna Metal Products Co., Ltd. is a joint venture established by Jiujiang Guanhuang Mould Co., Ltd. and Sihui Nanye Metal Plastic Products Co., Ltd. The company's two parent companies were established in 1984 and have a history of nearly 40 years.

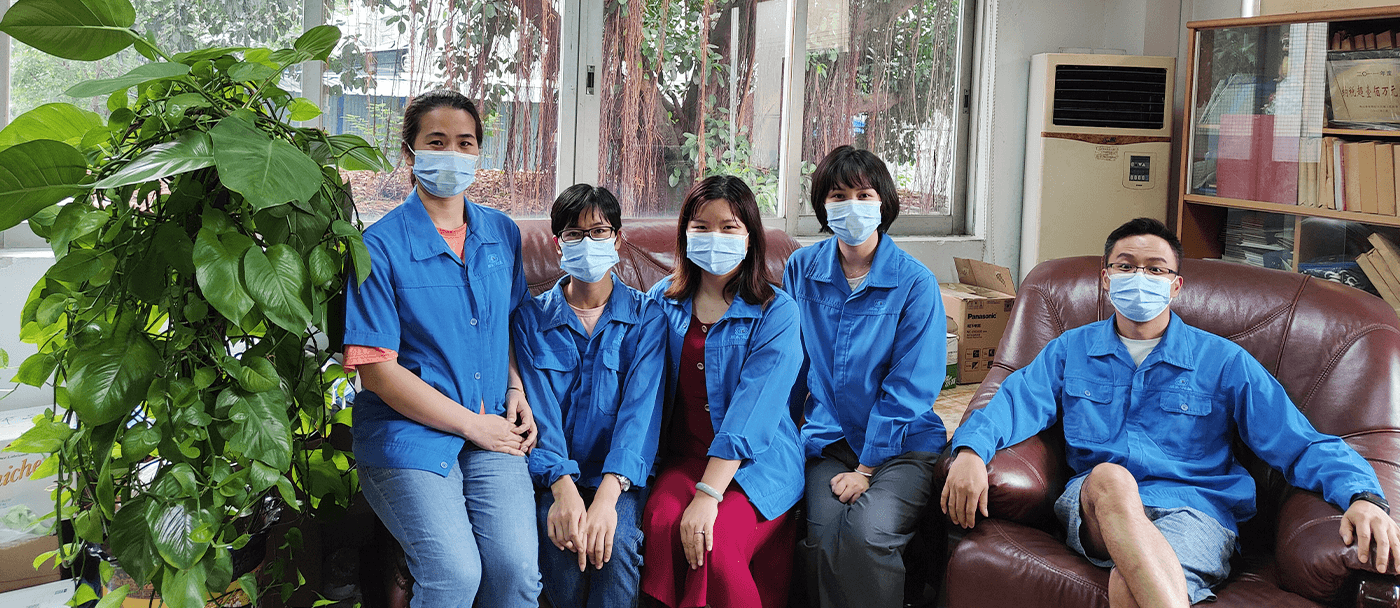

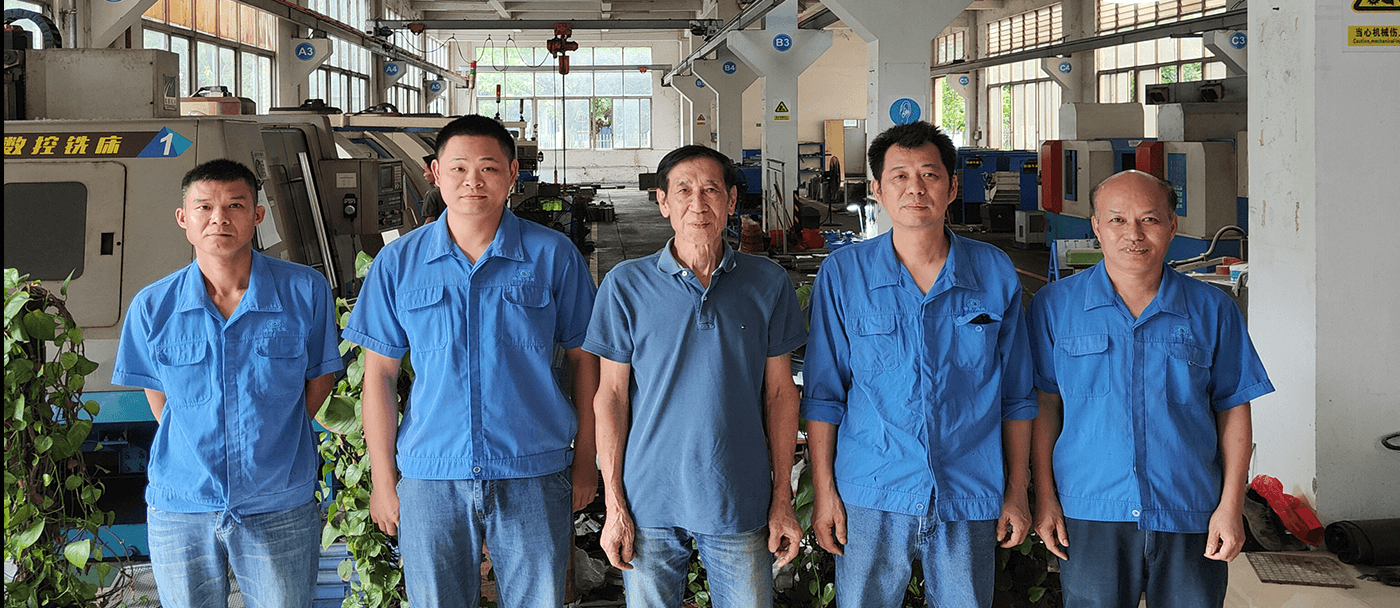

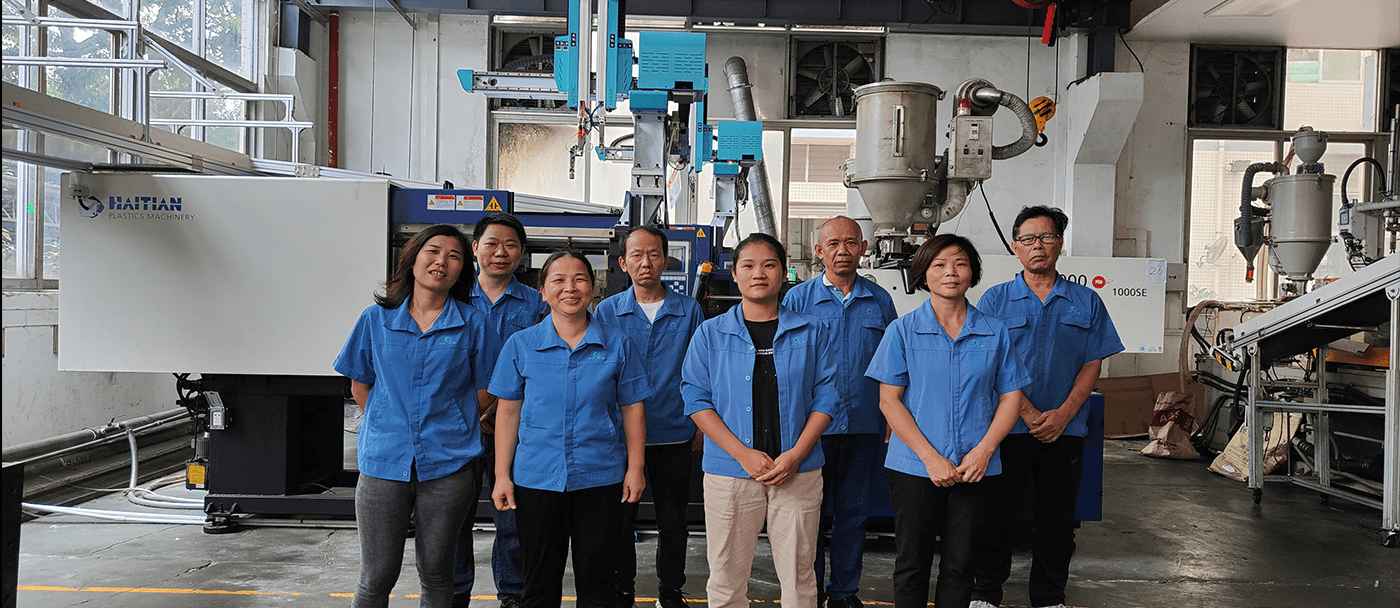

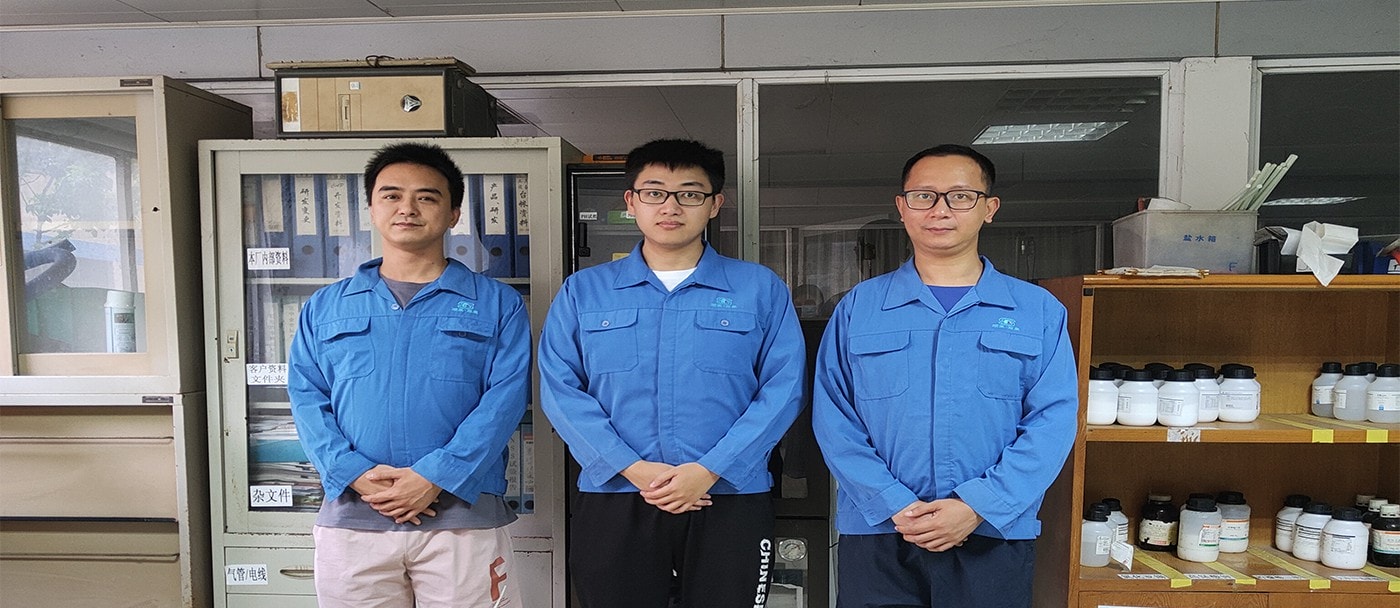

The company's two parks have a total area of 30,000 square meters, a total investment of 70 million yuan, and 300 employees, including 15 engineers. We have been focusing on the development and production of auto parts, motorcycle parts, small household appliances, bathroom accessories and other fields for many years.

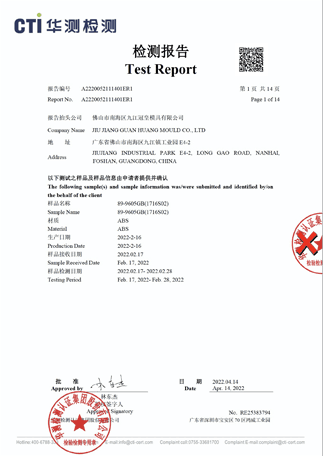

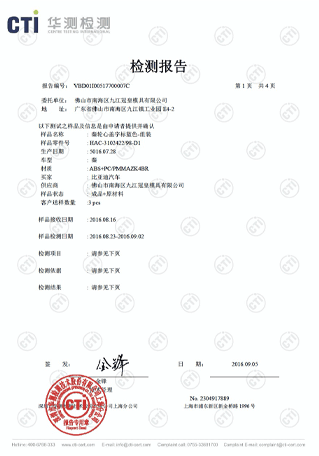

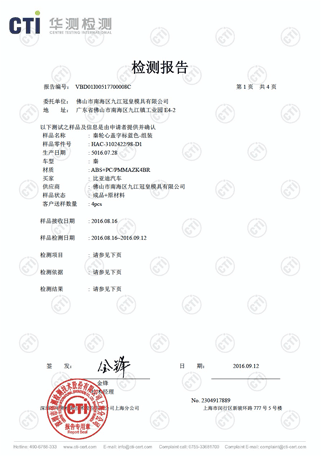

Over the years, the company has insisted on improving its management capabilities and product quality, and has successively obtained IATF16949:2016 certification、ISO9001:2000 quality management system certification and ISO14001-2004 environmental system certification.