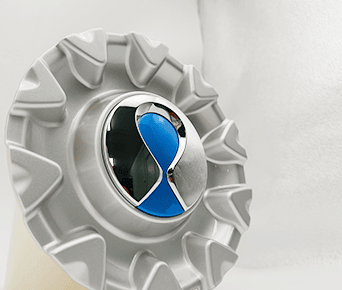

Lightweight: Aluminum alloys have low density, making them ideal for applications where weight is critical.

Lightweight: Aluminum alloys have low density, making them ideal for applications where weight is critical.

Strength: Aluminum alloy has a high strength-to-weight ratio, making it strong and durable, suitable for various scenarios.

Strength: Aluminum alloy has a high strength-to-weight ratio, making it strong and durable, suitable for various scenarios.

Corrosion Resistance: Aluminum alloys have a natural oxide layer that provides corrosion resistance, making them ideal for use in harsh environments.

Corrosion Resistance: Aluminum alloys have a natural oxide layer that provides corrosion resistance, making them ideal for use in harsh environments.

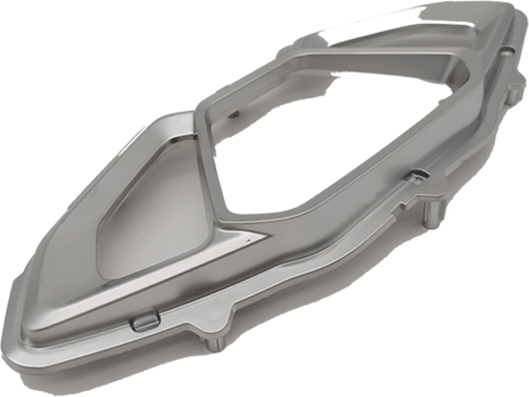

High precision: The aluminum alloy stampings process can produce complex and precise shapes with tight tolerances, resulting in high-quality finished products.

High precision: The aluminum alloy stampings process can produce complex and precise shapes with tight tolerances, resulting in high-quality finished products.

Versatility: Aluminum alloys are easily shaped and molded into a variety of shapes and sizes, making them ideal for a wide range of applications.

Versatility: Aluminum alloys are easily shaped and molded into a variety of shapes and sizes, making them ideal for a wide range of applications.

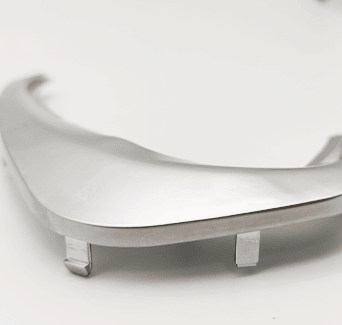

How to do aluminum alloy oxidation?

Aluminum stamping parts are a commonly used aluminum alloy manufacturing process. After the aluminum alloy oxidation, the oxide layer can be removed by the surface treatment method of aluminum stamping parts to make the surface smoother and more beautiful. Specific treatment methods include chemical oxidation, electrochemical polishing, mechanical polishing, etc. These methods are helpful to improve the corrosion resistance of aluminum alloys, and surface treatment can also be carried out according to requirements, such as spraying, anodizing, electrophoretic coating, etc. To increase its corrosion resistance and decorative properties.