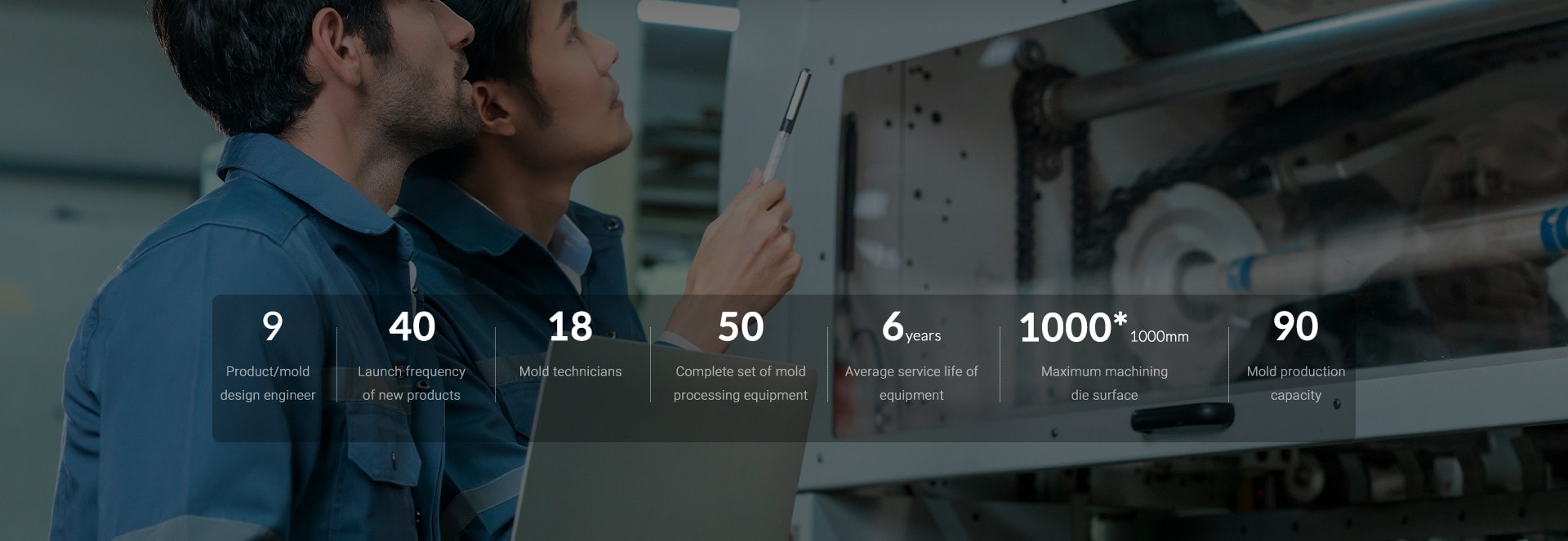

Plastic injection molding technology

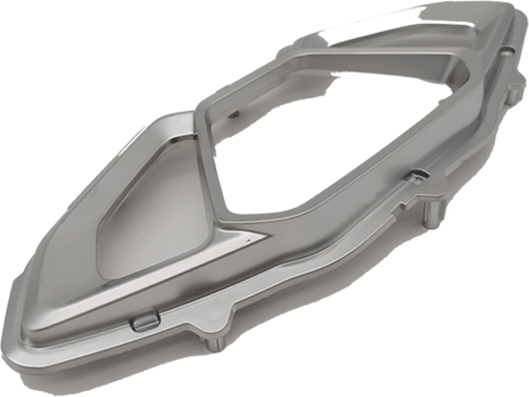

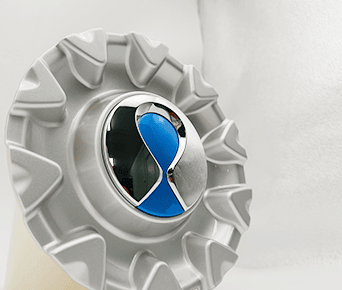

We offer plastic injection molding technology is a common plastic manufacturing process by injecting heated molten plastic material into a mold and forming it into the desired shape and size under high pressure. This technology used to create a wide variety of plastic parts, products and assemblies. Most commonly used for automotive parts, it is a versatile and efficient manufacturing process technology that can be used to mass-produce complex shapes and parts. It offers many advantages over other plastic injection molding manufacturing process, including lower production costs, faster production times, and the ability to create parts with high precision and accuracy.