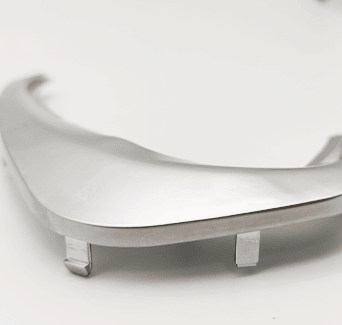

Stainless steel stamping parts

The stainless steel stamping parts are parts made of stainless steel stamping process. In the production process, first put the stainless steel plate into the punching machine, and use the mold to press, punch, bend and other processing, and finally form parts of various shapes. Stainless steel stamping parts have excellent corrosion resistance, high strength and high temperature resistance, and are widely used in automobiles, machinery, and other fields, such as body parts in automobile manufacturing, metal casings in electronic equipment, etc.