Over the past 30 years, Bozna has provided services to more than 3,000 customers, including the auto parts industry, motorcycle parts industry, small household appliances industry, bathroom industry and so on.

Learn Moreyears of production experience

molds owned count

employees

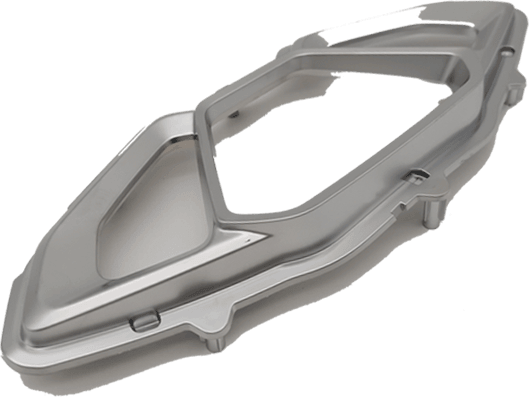

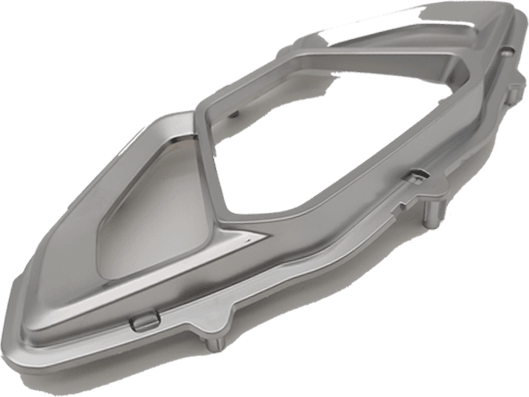

Our company has been focusing on product production for nearly 40 years, and is the first full-scale automobile wheel cover product supplier in China. While deeply cultivating the domestic market, our service area has been extended to many countries and regions in North America, Europe, Australia and Asia.

We have an excellent product engineer team with an average of more than 10 years of experience in product advance planning and process arrangement. We firmly believe that "simple structure, stable technology" is the soul of the product realization process, and will actively implement this consciousness into every link of the service, multi-department linkage, to realize the efficient flow of products in each process.

The company's production meets the requirements of IATF16949:2016 quality management system and has obtained the certification. Every employee can strictly follow the control plan and can implement every test item. The company has complete testing facilities and testing personnel, and has specific testing procedures.

In addition to meeting customers' demand for large quantities of products, we can also provide customers with personalized small batch customization services. Our daily output of finished products is more than 40,000 sets, which can meet the needs of customers. Our production cycle of the whole set of products can be completed within a week at the fastest, which can quickly meet the customer's demand for delivery cycle.

Within the modern manufacturing landscape, aluminum alloy stamping parts stand out for their combination of lightness, strength, and malleability. As a critical process in the production of intricate and durable components, aluminum alloy stamping has become indispensable in industries ranging from automotive to consumer electronics. This article will delve into the process of aluminum alloy stamping, its applications, and the ways in which it contributes to efficiency and innovation in global manufacturing.

In the realm of precision manufacturing, stainless steel stamping has emerged as a transformative process for industries worldwide. Known for its strength and corrosion resistance, stainless steel is pivotal in creating components that meet the rigorous standards of today's global trade environment. From the automotive sector to medical equipment manufacturing, the adaptability of stainless steel stamping parts makes them indispensable. This article will unravel the significance of stainless steel stamping in the manufacturing process, its role in product development, and its contributions to operational excellence in foreign trade.

As the backbone of modern manufacturing, plastic injection molding technology has been a catalyst for innovation in product development across the globe. This method not only streamlines manufacturing processes but also opens up new avenues for design and functionality, particularly in the fast-paced sector of foreign trade. In this comprehensive examination, we will navigate the strategic implementation of plastic injection molding technology, revealing its indispensable role in crafting products that meet contemporary market demands and drive industrial success.