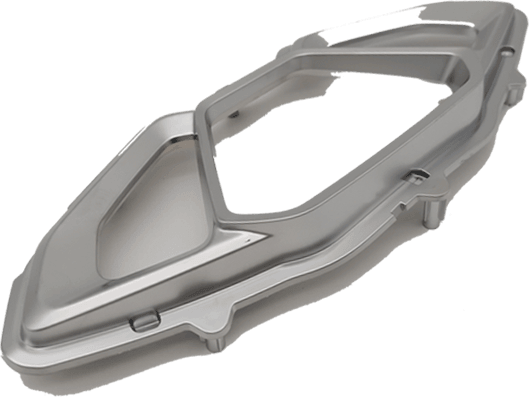

Within the modern manufacturing landscape, aluminum alloy stamping parts stand out for their combination of lightness, strength, and malleability. As a critical process in the production of intricate and durable components, aluminum alloy stamping has become indispensable in industries ranging from automotive to consumer electronics. This article will delve into the process of aluminum alloy stamping, its applications, and the ways in which it contributes to efficiency and innovation in global manufacturing.

Aluminum alloy stamping is a metal forming process that involves shaping aluminum sheets under high pressure. The unique properties of aluminum alloys, which include various grades with different strength-to-weight ratios and corrosion resistance, make them ideal for a multitude of applications. This section will explore the technical aspects of the stamping process, the selection of aluminum grades, and the design considerations that are paramount for creating high-quality stamped aluminum parts.

The utilization of aluminum alloy stamping parts is vast and varied. In the automotive industry, they provide the necessary balance between weight and performance, contributing to fuel efficiency and safety. In aerospace, the high strength and low weight of aluminum stamping parts are essential for aircraft design. Consumer goods also benefit from the aesthetics and conductivity of aluminum parts. This part will examine the widespread use of these components, illustrating their versatility and importance across different sectors.

When it comes to aluminum alloy stamping, the design and choice of material play a crucial role in the success of the final product. Engineers must account for factors such as material thickness, bend radii, and potential for springback. Additionally, the choice between various aluminum grades, like 6061 or 5052, each with its own set of properties, must be matched with the product's intended use. This segment will offer insights into how to make these critical decisions, ensuring that the end result is both functional and cost-effective.

The field of aluminum alloy stamping is continually advancing, with innovations that push the boundaries of what can be achieved. From the implementation of high-speed stamping presses to the integration of computerized control systems, these technological advancements allow for greater precision and efficiency. The latest trends and techniques in aluminum stamping will be discussed, highlighting how they enhance production capabilities and open up new possibilities for product development.

Maintaining quality in aluminum stamping is essential, given the critical applications of its products. This section will discuss the stringent quality control measures and standards that must be adhered to in the stamping process. Inspection methods, tolerance standards, and certifications will be covered, detailing how manufacturers ensure that each stamped part meets the highest standards of quality and reliability.

Cost management is a key concern in the production of aluminum alloy stamping parts. Efficient production processes not only lead to cost savings but also contribute to the sustainability of manufacturing operations. This part will explore the strategies manufacturers use to minimize waste, optimize energy use, and reduce production costs while maintaining the high quality of stamped parts.

Aluminum's recyclability makes aluminum alloy stamping a relatively sustainable manufacturing process. This section will delve into the sustainability practices within the aluminum stamping industry, including the use of recycled materials, the minimization of waste, and the reduction of the carbon footprint associated with production.

In conclusion, aluminum alloy stamping parts are a testament to the ingenuity and adaptability of modern manufacturing. This article has highlighted the process's versatility, its role in driving industry innovation, and its contribution to creating high-quality products across a variety of sectors. As manufacturers continue to seek out materials and processes that align with the demands of efficiency and sustainability, aluminum alloy stamping stands as a clear choice for the future of production in a competitive global marketplace.