As the backbone of modern manufacturing, plastic injection molding technology has been a catalyst for innovation in product development across the globe. This method not only streamlines manufacturing processes but also opens up new avenues for design and functionality, particularly in the fast-paced sector of foreign trade. In this comprehensive examination, we will navigate the strategic implementation of plastic injection molding technology, revealing its indispensable role in crafting products that meet contemporary market demands and drive industrial success.

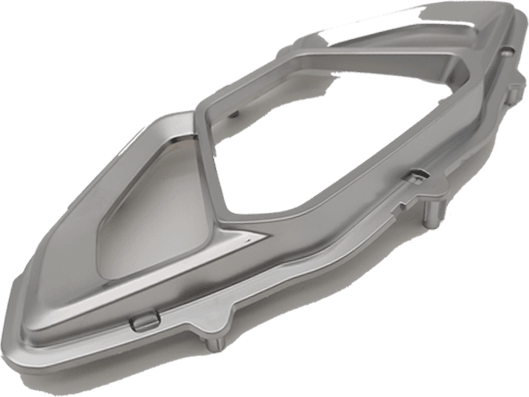

The advent of plastic injection molding has significantly expanded the horizons of product design. This technology allows designers to push the boundaries of complexity and precision, enabling the creation of components with intricate geometries that were once unattainable. This section will delve into the ways injection molding has redefined the prototyping phase, drastically reducing time from concept to market-ready product, and how this has become an invaluable asset in maintaining a competitive edge in the realm of foreign trade.

Plastic injection molding technology is not just shaping products; it's enhancing their performance and extending their lifespan. Through advances in material science, manufacturers can now select from a plethora of polymers that offer improved strength, heat resistance, or flexibility. This segment will explore how choosing the right material can result in products that not only perform better but also align with the rigorous durability demands of global logistics and trade operations.

In mass production, the imperative to minimize costs while maintaining product integrity is a delicate balance. Plastic injection molding technology addresses this need head-on with its capacity for high-volume output and consistent repeatability. In this section, we discuss cost-effective strategies such as the employment of multi-cavity molds that multiply output per cycle, and the integration of automation to reduce labor costs. We will also touch on the selection of materials and design optimizations that reduce cycle times and material waste, further driving down production expenses. These strategies are particularly relevant for businesses in the foreign trade sector looking to optimize their supply chain and maximize profit margins.

The ability to swiftly adapt to market changes is a defining characteristic of successful businesses in the modern economy. Plastic injection molding offers manufacturers the agility required to respond to evolving consumer preferences and emerging market trends. This section will investigate how quick mold modifications, scalable production, and the capacity to work with a diverse range of materials make plastic injection molding an ideal technology for businesses aiming to stay responsive and resilient in the face of rapid market shifts.

The plastic injection molding industry is at a crossroads with sustainability. As environmental concerns take center stage, manufacturers are seeking ways to adapt their practices. This part of the article will examine how the industry is embracing green initiatives, from integrating energy-efficient machines that reduce the carbon footprint to implementing recycling programs that repurpose plastic waste. We will provide insights into how companies can incorporate these practices not only to benefit the environment but also to enhance their market positioning and comply with international environmental regulations.

To conclude, plastic injection molding technology remains a dynamic force in the manufacturing sector, offering a path to sophisticated product development that aligns with the economic and ecological demands of our time. This article has traversed the various dimensions of this technology—from design innovation and material selection to cost management and sustainability—underscoring its significance in shaping the future of foreign trade. Businesses that harness the capabilities of plastic injection molding can expect to achieve not just immediate gains in productivity but also long-term growth and sustainability.