Aluminum alloy stamping parts play a vital role in modern industry. Their lightness, strength and versatility make them the material of choice in a variety of fields. Whether in automobile manufacturing, aerospace, electronic equipment or construction industries, aluminum alloy stampings are widely used to provide performance and efficiency improvements for various products. This article will explore the characteristics, application areas and importance of aluminum alloy stampings in modern industry.

Lightweight: Aluminum alloy is a lightweight material with good strength and stiffness. This makes aluminum alloy stampings ideal for areas such as automobiles, aircraft and spacecraft, as they can reduce overall weight, improve fuel efficiency and reduce energy consumption.

Strong: Although aluminum alloys are lightweight, they offer excellent corrosion resistance and durability. This allows them to maintain stability for long periods of time in harsh environments without the need for frequent maintenance and replacement.

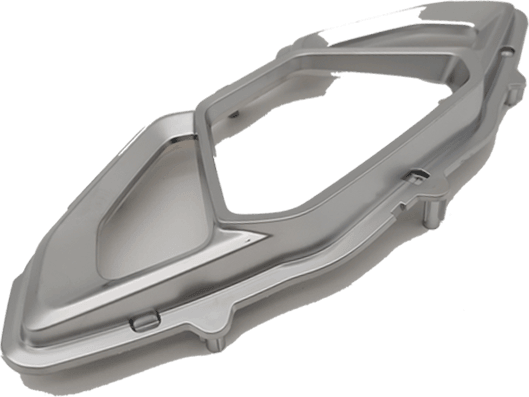

Plasticity: Aluminum alloys are easy to machine and stamp, so parts can be manufactured in a variety of shapes and sizes. This plasticity makes them ideal for manufacturing complex industrial parts and assemblies.

Electrical Conductivity: Aluminum alloys have good electrical conductivity, making them very useful in electronic devices and electrical applications. They can be used to make components such as heat sinks, wires and connectors.

Automobile manufacturing: Aluminum alloy stamping parts are widely used in automobile manufacturing to manufacture body parts, engine parts and suspension systems. They help reduce the overall weight of the car, improve fuel efficiency, and provide better performance and safety.

Aerospace: In the aerospace and aerospace sectors, lightweighting is key. Aluminum alloy stampings are used to manufacture aircraft wings, fuselages and spacecraft components to improve flight efficiency and load capacity.

Electronic equipment: Aluminum alloy stamping parts are used to manufacture housings, heat sinks and connectors for electronic equipment. They help maintain the proper operation of equipment and dissipate heat, ensuring the performance of electronic components.

Construction Industry: In the construction industry, aluminum alloy stampings are often used to manufacture window frames, door frames, and other structural components. Their lightweight nature makes buildings easier to install and maintain.

The importance of aluminum alloy stampings lies not only in their wide range of applications, but also in their sustainable and environmentally friendly properties. Aluminum alloys can be recycled and reused, helping to reduce resource waste and environmental impact.