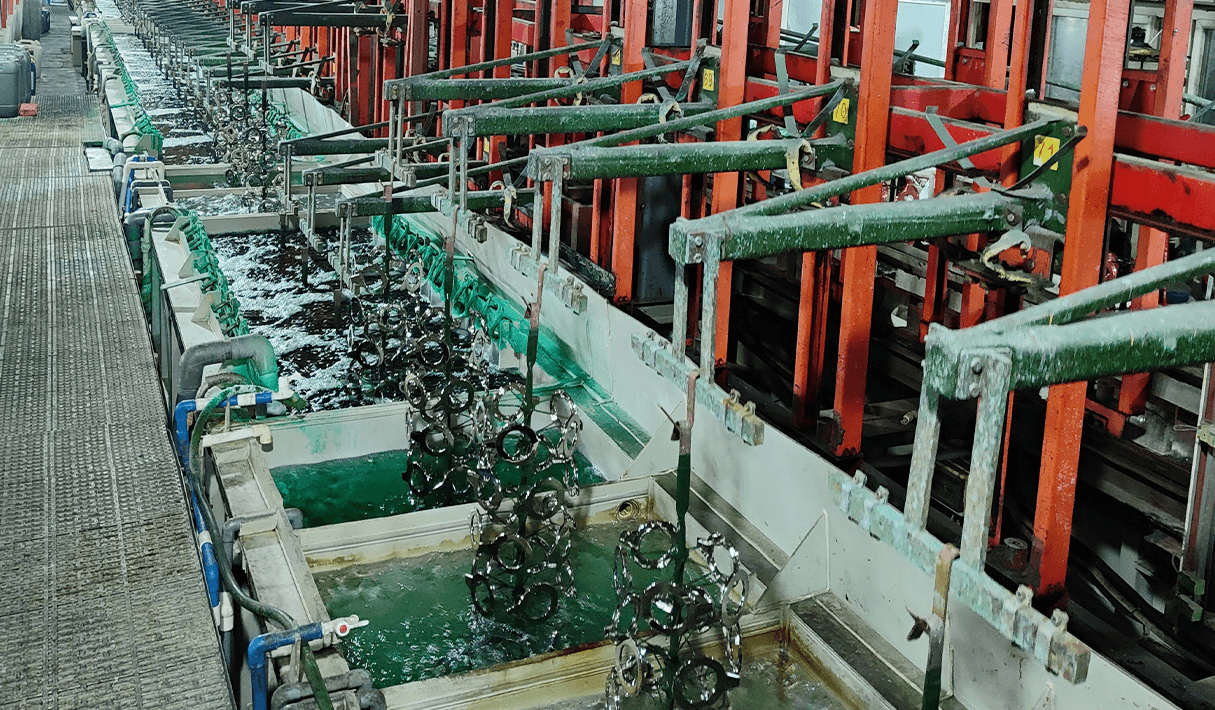

Automatic electroplating production line

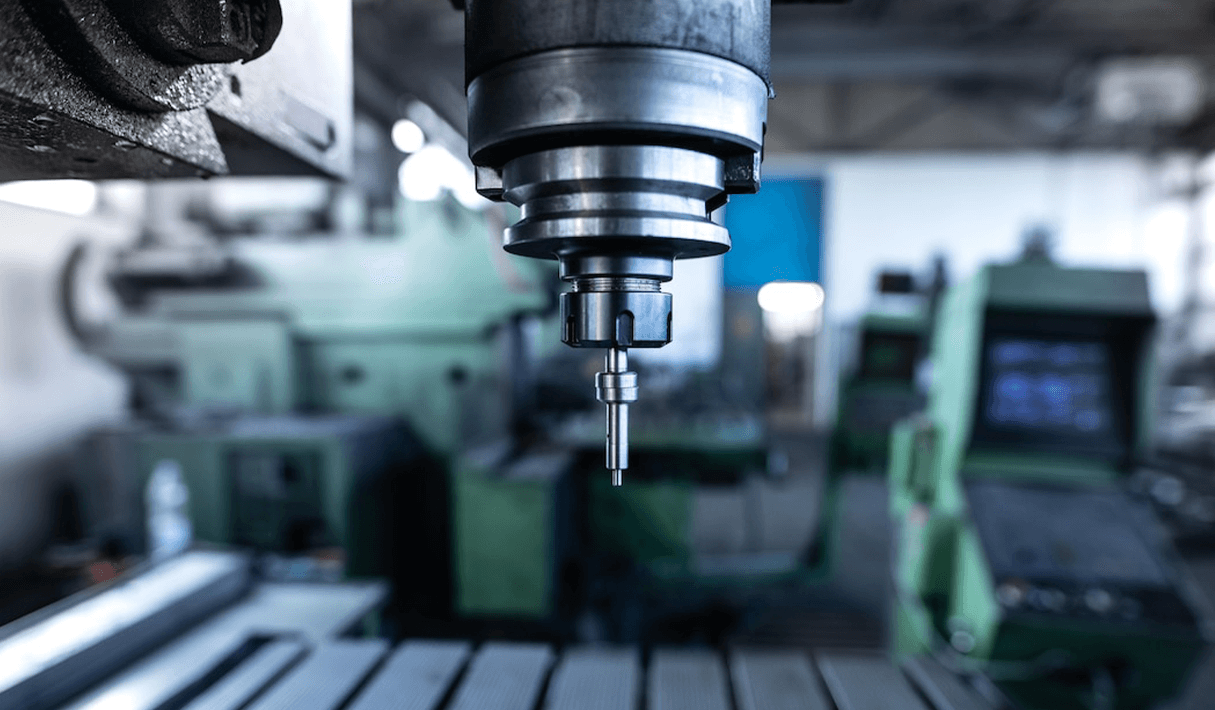

We have a automatic electroplating production line, providing high quality vacuum electroplating and water electroplating, satisfying the demand for unsatisfactory materials and metal spray electroplating. Through advanced automation technology, we are able to produce high-efficiency, high-precision electrical machining, so as to provide customers with superior products.