Stainless steel stamping process

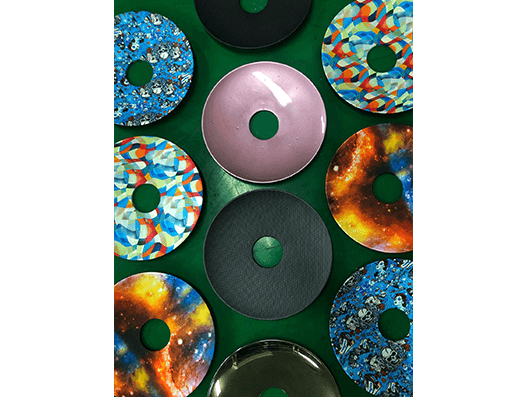

The water transfer printing process is widely used in the automotive industry to decorate car parts, Here are the steps involved in water transfer printing:

Prepare the surface: The surface of the object to be printed must be cleaned and prepared properly. This involves removing any dirt, grease, or other contaminants that may interfere with the printing process.

Prepare the surface: The surface of the object to be printed must be cleaned and prepared properly. This involves removing any dirt, grease, or other contaminants that may interfere with the printing process.

Apply base coat: A base coat is applied to the surface of the object to create a solid color foundation for the design.

Apply base coat: A base coat is applied to the surface of the object to create a solid color foundation for the design.

Print the design: A water-soluble film with the desired design or pattern is floated on the surface of a water tank. The film dissolves in the water, leaving the ink on the surface of the water.

Print the design: A water-soluble film with the desired design or pattern is floated on the surface of a water tank. The film dissolves in the water, leaving the ink on the surface of the water.

Activate the film: An activator solution is sprayed onto the surface of the film, which dissolves the ink and activates it, making it ready to transfer onto the object.

Activate the film: An activator solution is sprayed onto the surface of the film, which dissolves the ink and activates it, making it ready to transfer onto the object.

Dip the object: The object is slowly dipped into the water tank, allowing the ink to transfer and adhere to the surface of the object.

Dip the object: The object is slowly dipped into the water tank, allowing the ink to transfer and adhere to the surface of the object.

Rinse and dry: Once the object is fully submerged, it is removed from the water and rinsed to remove any excess film or ink. The object is then allowed to dry.

Rinse and dry: Once the object is fully submerged, it is removed from the water and rinsed to remove any excess film or ink. The object is then allowed to dry.

Apply topcoat: A clear topcoat is applied to the surface of the object to protect the design and provide a glossy finish.

Apply topcoat: A clear topcoat is applied to the surface of the object to protect the design and provide a glossy finish.